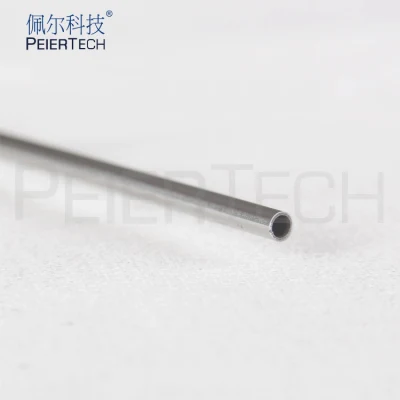

Factory Supply Exhaust Titanium Alloy Material Metal Tube

Factory supply exhaust Titanium alloy material metal tube Specifications of Titanium Seamless and Welded Tubing We provi

Basic Info

| Model NO. | Titanium alloy |

| Type | Titanium Pipes |

| Application | Industrial, Medical, Heat Exchanger |

| Technique | Seamless |

| Grade | Gr1 Gr2 Gr3 Gr5 Gr7 Gr9 |

| Shape | Round |

| Density | 4.5g/cm3 |

| Surface | Pickled |

| Diameter | 3-114mm |

| Thickness | 0.2-5mm |

| Length | Within 15000mm |

| Standards | GB, Gjb, ASTM, AMS, BS, DIN, DMS, JIS |

| Material Grade | Gr1, Gr2, Gr3, Gr5, Gr7, Gr12 |

| Application1 | :Industrial, Medical, Petrochemical Industry, etc |

| Certificates | SGS/ISO9001:2015 |

| Test | Eddy Current Test,Tensile Strength Test,Hydraulic |

| Processing | Hot Rolled,Cold Rolled,Forge,Cold Drawn |

| Surface1 | Polished,Bright Finished,Pickling, Sand-Blast etc |

| Transport Package | Wooden Box |

| Specification | 1000*2000mm |

| Trademark | ZX. TIG |

| Origin | Shaanxi, China |

| HS Code | 8108904010 |

| Production Capacity | 60000t/a |

Product Description

Factory supply exhaust Titanium alloy material metal tube

Specifications of Titanium Seamless and Welded Tubing

| Category | Process | Outer Diameter | Wall Thickness | Length | Grades |

| Titanium Seamless Tube /Pipe | Hot Extruded | 25-210mm | 4-30mm | Customized | Gr1 Gr2 Gr3 Gr5 Gr7 Gr9 Gr11 Gr12 |

| Cold-rolled | 1.5-80mm | 0.2-5.5mm | Customized | ||

| Titanium Welded Tube/Pipe | Welded | 10-38mm | 0.5-2.1mm | Customized |

We provide following tests for Ti seamless and welded tubes

| Chemical Composition | Visual Inspect | Ultrasonic Testing | Current Testing |

| Flattening Testing | Flattening Testing | Pneumatic Test | Hydrostatic Test |

| Tensile | Yield | Hardness | Elongation |

Chemical Composition

| Grade | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

| Grade | Elongation(%) | Tensile Strength (Min) | Yield Strength (Min) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |

- Marine Industry

- Chemical and petrochemical industry

- Pulp and paper industry

- Sporting goods - golf shafts, bicycle frames, etc.

- Medical industry

- Nuclear industry

| Product name | Specification |

| Titanium Ingots | Ф360mm~Ф1020mm,the maximum weight is up to 12t |

| Titanium Slab | (80~400)mm×(~1500)mm×(~2600)mm |

| Titanium Forgings | Weight per piece≤2000kg |

| Titanium Hot-rolled plates | (4~100)mm×(800~2600)mm×(2000~12000)mm |

| Titanium Cold-rolled plates | (0.01~4.0)mm×(800~1560)mm×( ~6000) mm |

| Titanium Strips | (0.01~2.0)mm×(800~1560)mm×L |

| Titanium Tubes / Pipes | Ф(3~114)mm×( 0.2~5)mm × (~15000)mm |

Titanium Grade | ·GR1, GR2, GR3, GR5, GR7, Gr9, Gr11, GR12 ·BT1-00,BT1-0,BT1-2 BT6 BT5-1 3B BT6c ·TA0,TA2,TA3,TA5,TA6,TA7,TA9,TA10,TB2,TC1,TC2,TC3,TC4 |

| Category | Material | Dimension(mm) | Specification |

| Titanium & Alloy ingots & bars | CP Ti,Ti-6Al-4V, Ti-6Al-4V Eli,Ti-3Al-2.5V,Ti-5Al-2.5Sn, Ti-5Al-2.5Sn Eli,Ti-0.05Pd, Ti-0.2Pd, Ti-6Al-7Nb,Ti-13Nb-13Zr,Ti-0.1Ru,Ti-3Al-8V-6Cr-4Mo-4Zr,Ti-6Al-4V-0.1Ru,Etc. | Standardorcustomized | GB/T 2965, ASTM B348 |

| Titanium & Alloy castings | GB/T 6614, ASTM B367 | ||

| Titanium & Alloy forgings | GB/T 25137, ASTM B381 | ||

| Titanium & Alloy plates | GB/T 3621, ASTM B265 | ||

| Titanium & Alloy strips & foils | GB/T 3622, ASTM B265 | ||

| Cold rolled Titanium & Alloy strip coils | GB/T 26723, ASTM B265 | ||

| Titanium & Alloy wires | GB/T 3623, ASTM B863 | ||

| Titanium & Alloy seamless tubes | GB/T 3624, ASTM B861 | ||

| Titanium & Alloy welded tubes | GB/T 26057, ASTM B862 | ||

| PM Titanium & Alloy components | GB/T 6887, ASTM B817 |

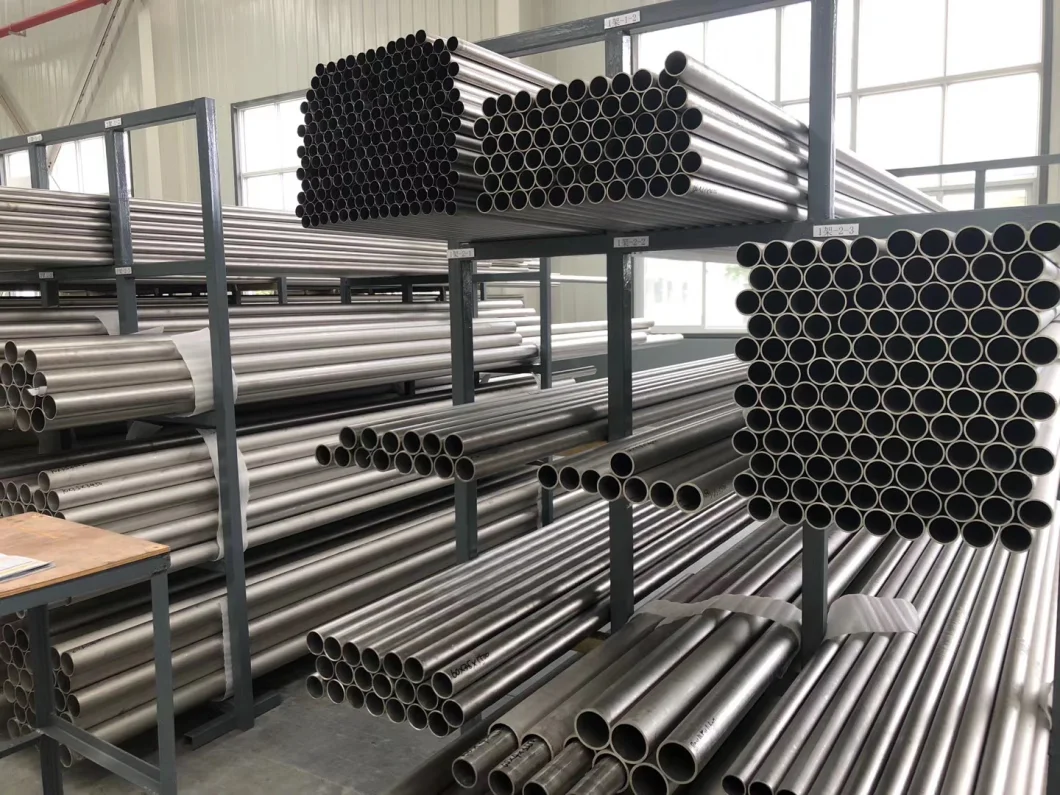

Titanium Production Process

Titanium Production Equipment About Us

Why Choose Us?

- 53 years of titanium R&D and production experience

- Our products have been exported to more than 30 countries all round the world

- State-owned company with great credit and strong financial strength

- Competitive price,best service, strict quality control system and on-time delivery

- Related Supply Chain Service

Contact Us XI'AN JOINXIN NEW MATERIAL TECHNOLOGY CO.,LTD

Factory Address: 22nd Floor, Kerry B, Wei Yang Dist., Xi'an 710018, PRC.

Send to us