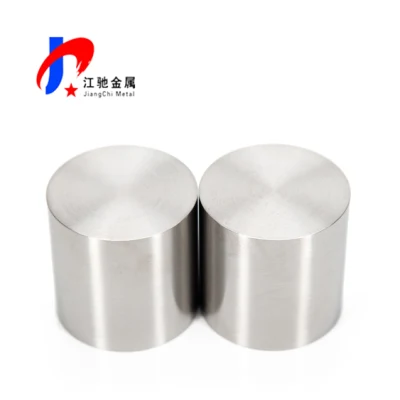

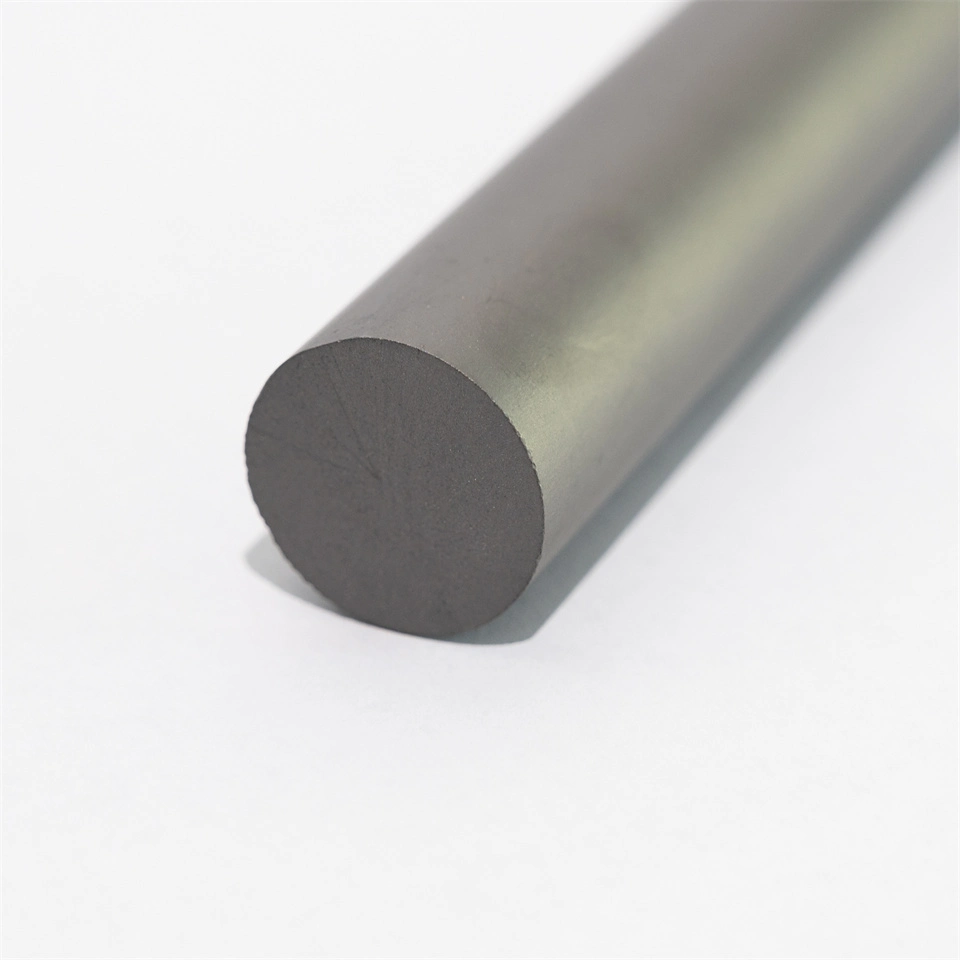

Tungsten Carbide Rods Bar for Cutting Tools, Drill Tools and Ware Parts

Basic Info

| Model NO. | K5/K10/K20/K30/K40 |

| Material | Alloy |

| Application | Metal Cutting Machine, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Engraving Machinery |

| Chemical Composition | Wc+Co |

| Lead Time | Within 15days |

| Type | Power Tool Parts |

| Adavantages | 20 Years Experience in Carbide Tips Feild |

| Logo | Customized Log and Packing Are Available |

| Transport Package | Paper Wrapped Inside, Plastic Box or Wooden Case O |

| Specification | according to size adjustable |

| Trademark | OWN |

| Origin | China |

| HS Code | 8207909000 |

| Production Capacity | 500tons |

Product Description

Product Description1.High Quality carbide Rods ISO9001-2015 certified

2.Automatic pressing, HIP sintering technology

3.Good abrasion resistance and high hardness

4.Prompt aftersales service within 24 hours

5.OEM and customzied order are accepted

6.Diameter from 3-25mm, overal length 20mm to 330mm

7.Suitable for making drill bits,end mills,reamers and PCB tools etc.

| Grade | Hardness ≥HRA | TRS Mpa | Density g/cm3 | Applications recommended |

| YG6X | 91 | 1700 | 14.4-14.9 | Suitable for the finish machining of chilled cast iron, ductile cast iron, nonferrous metal and nonmetal. |

| YG10X | 90 | 2000 | 14.3-14.6 | Good commonality, high hardness and toughness. Suitable for manufacturing various kinds of integral end mills. |

| YL10.2 | 91.5 | 4000 | 14.45 | Suitable for nonferrous metal, cast iron, carbon steel, stainless steel, heat-resisting alloy steel. |

| JL10 | 90.5 | 2200 | 14.2-14.5 | Good commonality, high hardness and TRS. Using for the semifinishing of steel and nonferrous steel. |

| JL15 | 91.5 | 2400 | 14.5-15.0 | Fine particle size product. Good wear resistance and shock resistance. Using for the semifinishing and finish maching of various metal and nonmetal. |

| JL20 | 92.5 | 3000 | 14.7-15.1 | Fine particle size product. Good wear resistance and shock resistance. Using for the finish maching of various metal and nonmetal. Also used for maching heat-resisted steel, stainless steel, nickel base, high-temperature alloy. |

Q: Are you trading company or manufacturer ?

A: We are a Group company , manufacturer of tungsten carbide since 1989 andprofessinal own export company,and we We can supply 20 tons tungsten carbide product per month. We can provide customized carbide products as per your requirements.

Q: How long is your delivery time?

A: Generally,it will take 7 to 15 days after order confirm.The specific delivery time depends on the specific product and the quantity you needed.

Q: Do you provide samples? iIs it free or charged?

A:Yes, we can offer a sample for free charge but the freight is at customers' cost.

Q. Do you test all your goods before delivery?

A: Yes, we will do 100% test on our cemented carbide products before delivery.

To offer you the quick and professional service,please provide us the following information:

Tungsten carbide grades

Type / dimension / draft

Available tolerance

Available surface toughness

If you have no idea above information,please contact us freely

Sophia Sun