Hot Sale Heat Plate Molybdenum Foil with Molybdenum Concentrate

Basic Info

| Application | Aviation, Electronics, Industrial |

| Standard | JIS, DIN, ASTM |

| Purity | >99.95% |

| Alloy | Non-alloy |

| Type | Molybdenum Plate |

| Powder | Not Powder |

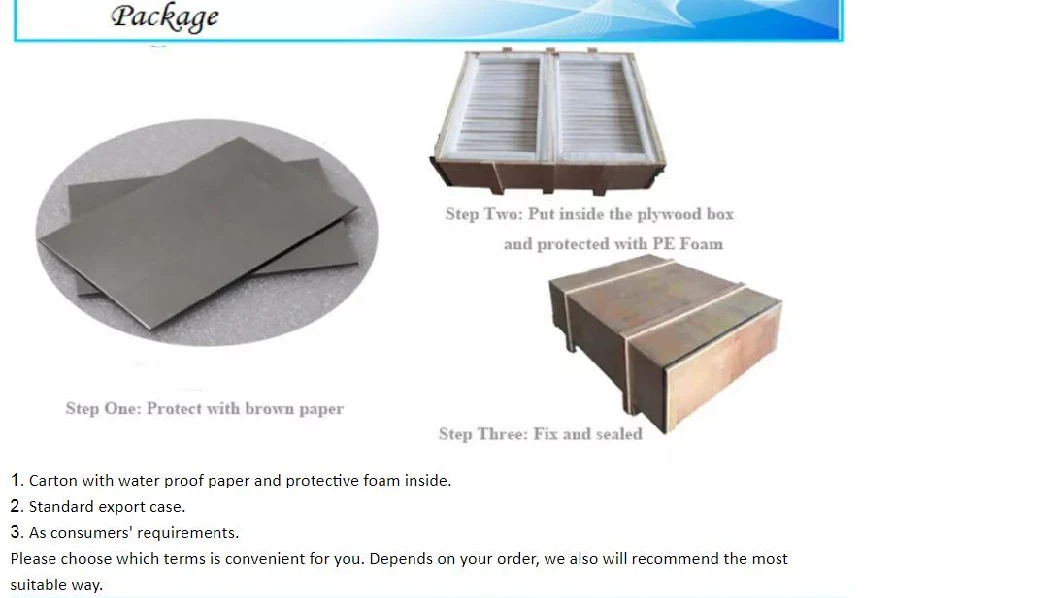

| Transport Package | Standard Export Packaging |

| Specification | as required |

| Trademark | as required |

| Origin | China |

| Production Capacity | 50000mt/Month |

Product Description

Category

1.1.1 Molybdenum 360-Unalloyed vacuum arc-cast molybdenum. vacuum fused molydenum

1.1.2 Molybdenum 361-Unalloyed powder metallurgy molybdenum.

1.1.3 Molybdenum Alloy 363-Vacuum arc-cast molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy.

1.1.4 Molybdenum Alloy 364-Powder metallurgy molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy.

1.1.5 Molybdenum 365-Unalloyed vacuum arc-cast molybdenum, low carbon.

1.1.6 Molybdenum Alloy 366-Vacuum arc-cast molybdenum-30 % tungsten alloy.

We normally produce Molybdenum 361, molybdenum 364. Also molybdenum-lanthanum alloy if requested.

Product information

Item | factory supply vacuum fused molybdenum sheet Price |

Standard | ASTM B386, GB/T3876 |

Grade | Mo1, 361 |

Material | 99.95% min. Mo |

Density | 10.2g/cm3 |

Melting Point | 2610 Centigrade |

Using temperature | 1400 Centigrade max. |

Size | Thick 0.025mm min. x W600mm max. x L3000mm max. |

Processing | Cold rolled, Stress relief annealing, Hot rolled |

Colour | Black or bright |

Package | Standard wooden case as your request |

Feature

1. Low thermal expansivity

2. High using temperature

3. Good corrosion resistence

4. High strength

5. Low electrical resistivity

Surface:shiny, acid pickling, satin, or as-rolled condition; dependent upon thickness and width parameters.Normal condition: cold-rolled bright, acid pickling, polished