Radiation Shielding Parts High Density Heavy Tungsten Alloy

Tungsten Alloy (Tungsten Heavy Alloy) Main Application: For making rotors of dynamic intertial materials, the stabilizer

Basic Info

| Model NO. | Factory Standard |

| Material Grade | Gmw |

| W Content | 50% - 90% |

| Balance | Nife or Nicu |

| OEM | Acceptable |

| Density | 17 - 18.5 g/cm3 |

| Surface | Machined or Ground |

| Transport Package | as Per Customers′ Request. |

| Specification | ISO9001: 2000 |

| Trademark | Fotma |

| Origin | P. R. China |

| HS Code | 81019910 |

| Production Capacity | 500t Per Year |

Product Description

Tungsten Alloy (Tungsten Heavy Alloy) Main Application: For making rotors of dynamic intertial materials, the stabilizers of aircraft wings, shielding materials for radioactive materials, containers in hospitals and for radioactive isotope (Cobalt 60), and for material of armor piercing bullets and moulds, etc.Tungsten Alloy Advantages:-High density-Excellent mechanical properties such as high vibration-damping capacity and high Young's modulus.-Excellent radiation-shielding property-High thermal conductivity with low thermal expansion coefficient-Higher high-temperature strength and thermal shock resistance-High oxidation resistance and corrosion resistance**We supply this material as per customerized sizes and properties.Tungsten Alloy Specifications:| Alloy Type(%) | HD17 90 W6 Ni4 Cu | HD17D 90 W7 Ni3 Fe | HD17.5 92.5 W5.25 Ni2.25 Fe | HD17.6 92.5 WBalanceNi, Fe, Mo | HD17.7 93 WBalanceNi, Fe, Mo | HD18 95 W3.5 Ni1.5 Cu | HD18D 95 W3.5 Ni1.5 Fe | HD18.5 97 W2.1 Ni.9 Fe |

| MIL-T-21014 | Class 1 | Class 1 | Class 1 | - | - | Class 3 | Class 3 | Class 4 |

| SAE-AMS-T-21014 | Class 1 | Class 1 | Class 2 | - | - | Class 3 | Class 3 | Class 4 |

| AMS 7725 C | 7725 C | 7725 C | -- | -- | -- | -- | -- | -- |

| ASTM B777-87 | Class 1 | Class 1 | Class 2 | - | - | Class 3 | Class 3 | Class 4 |

| Typical Density(g/cc) | 17.1 | 17.1 | 17.5 | 17.6 | 17.7 | 18 | 18 | 18.5 |

| Typical Density(lbs/in3) | 0.614 | 0.614 | 0.632 | 0.636 | 0.639 | 0.65 | 0.65 | 0.668 |

| Typical Hardness RC | 24 | 25 | 26 | 30 | 32 | 27 | 27 | 28 |

| Ultimate Tensile Strength Min(ksi) | 110,000 | 120,000 | 114,000 | 120,000 | 125,000 | 110,000 | 120,000 | 123,000 |

| 0.2% Offset Yield Strength Min(ksi) | 80,000 | 88,000 | 84,000 | 90,000 | 95,000 | 85,000 | 90,000 | 85,000 |

| Minimum % Elongation(1" gage length) | 6 | 10 | 7 | 4 | 4 | 7 | 7 | 5 |

| Proportional Elastic Limit(PSI) | 45,000 | 52,000 | 46,000 | 55,000 | 60,000 | 45,000 | 44,000 | 45,000 |

| Modulus of Elasticity(x106psi) | 40 x 106 | 45 x 106 | 47 x 106 | 52 x 106 | 53 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Coefficient of Thermal Expansion x10-6/0C(20-400C) | 5.4 | 4.61 | 4.62 | 4.5 | 4.5 | 4.43 | 4.6 | 4.5 |

| Thermal Conductivity(CGS Units) | 0.23 | 0.18 | 0.2 | 0.27 | 0.27 | 0.33 | 0.26 | 0.3 |

| Electrical Conductivity(% IACS) | 14 | 10 | 13 | 14 | 14 | 16 | 13 | 17 |

| Magnetic | No | Slightly | Slightly | Slightly | Slightly | No | Slightly | Slightly |

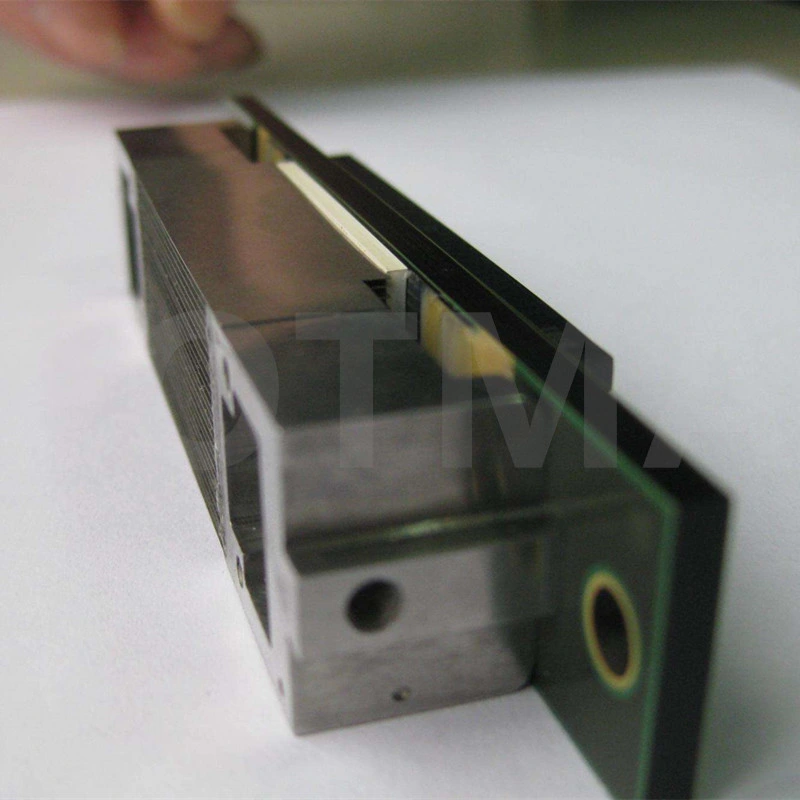

Production Show:

Send to us