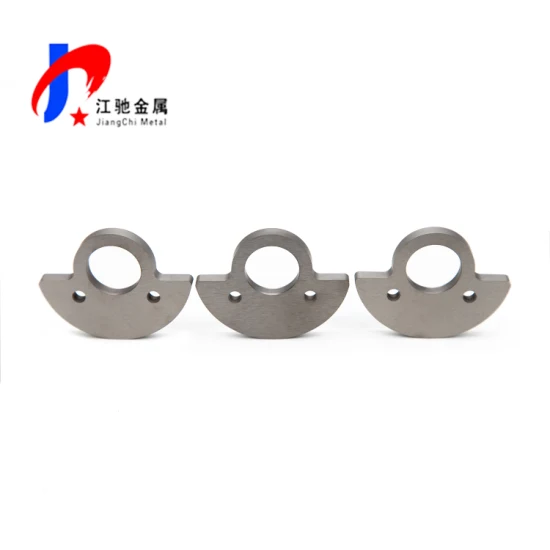

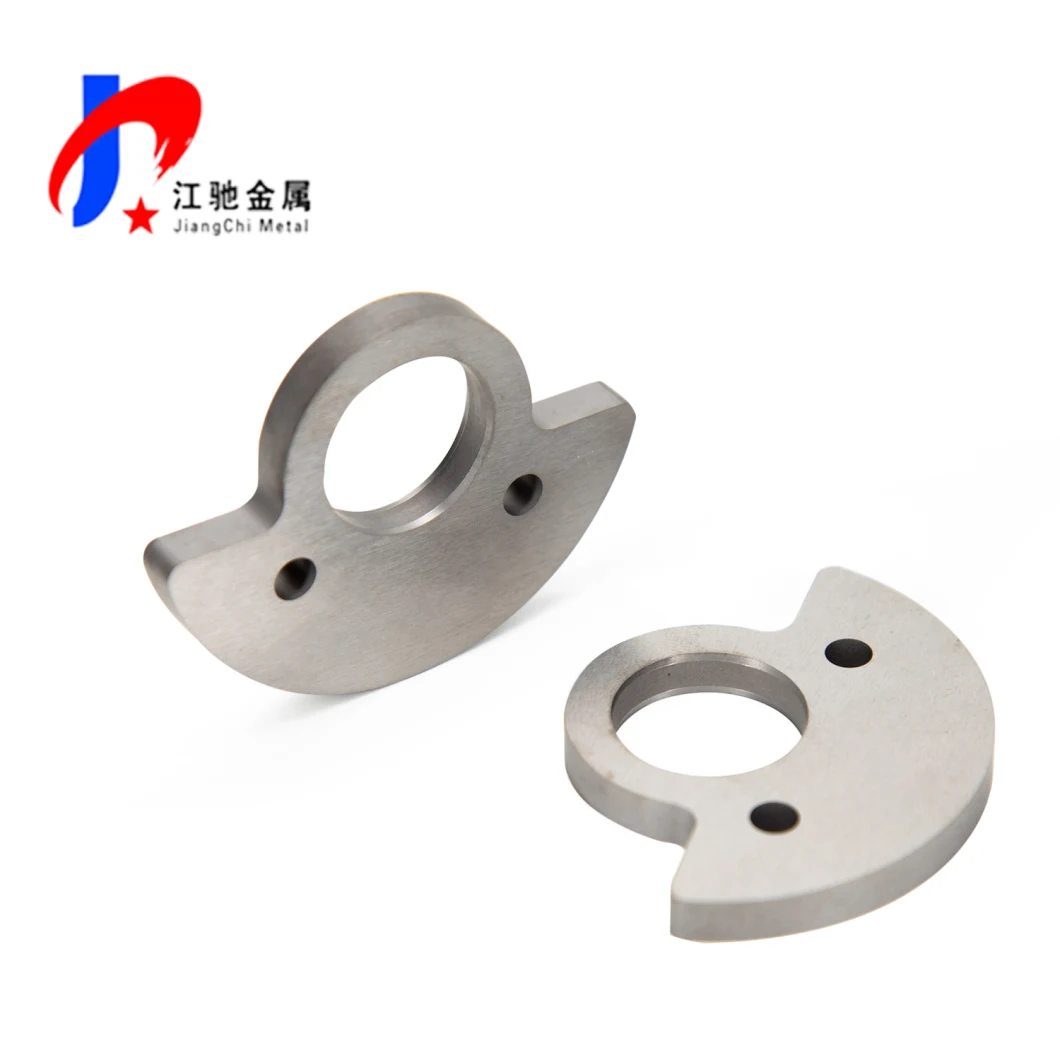

Heavy Tungsten Alloy (special shape part) Used for Heat Sink Tungsten Alloy W92.5nife

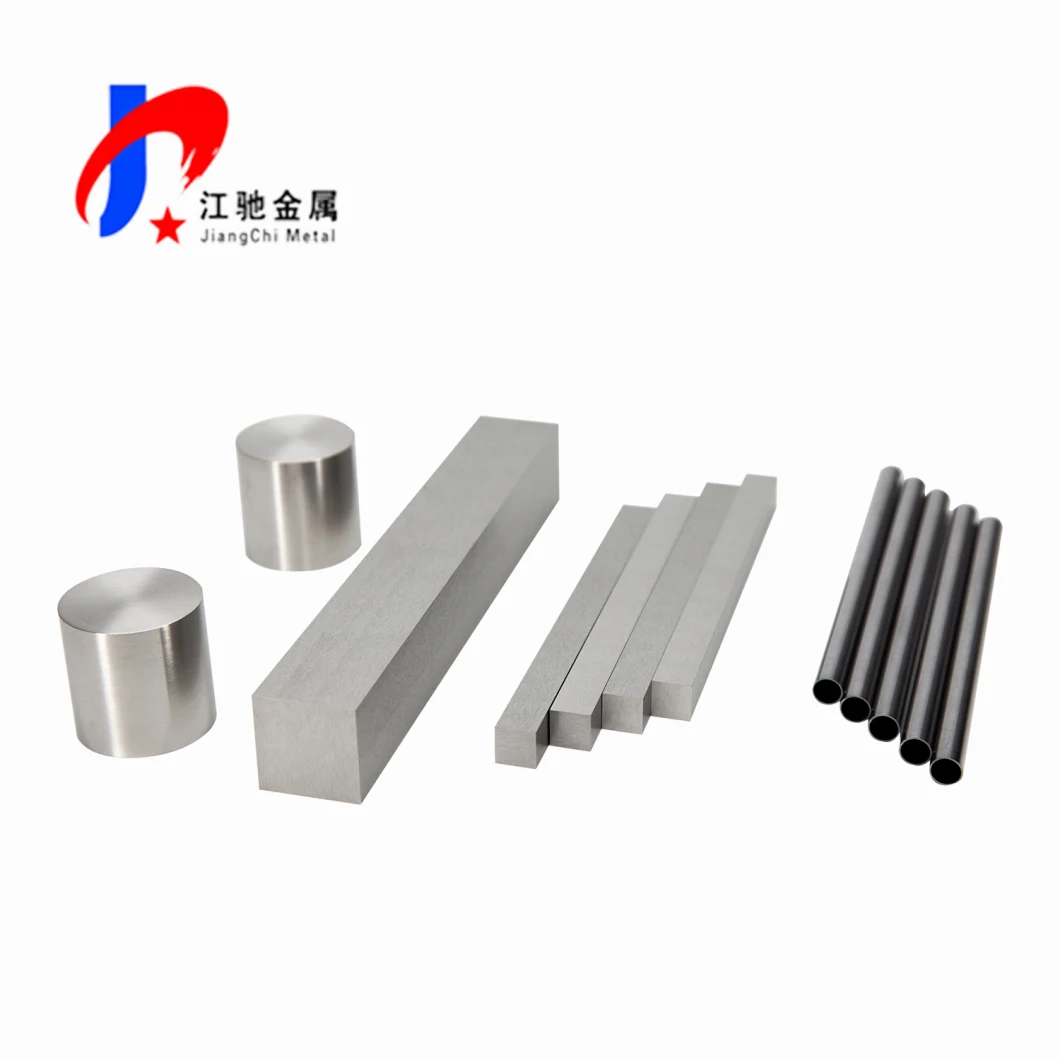

High Quality Tungsten High Heavy Alloy rods/sheet/tubes Tungsten Nickel Copper/Iron Alloy WNiCu (W90Ni6Cu4, W90Ni7Cu3, W

Basic Info

| Model NO. | W alloy |

| Density | >16.8g/cm3 |

| Grade | W90nife W92nife W95nife W97nife |

| Transport Package | Wooden Box |

| Specification | dia(1.5-200)*Length<500mm |

| Trademark | Jiangchi |

| Origin | China |

| HS Code | 8101990000 |

| Production Capacity | 100t/Year |

Product Description

High Quality Tungsten High Heavy Alloy rods/sheet/tubesTungsten Nickel Copper/Iron Alloy

WNiCu (W90Ni6Cu4, W90Ni7Cu3, W92NiCu, W925NiCu,W95, W97.5, etc)

WNiFe (W90Ni7Fe3, W90NiFe, W92NiFe, W92NiFe, W93NiCu,W95, W97.5, etc)

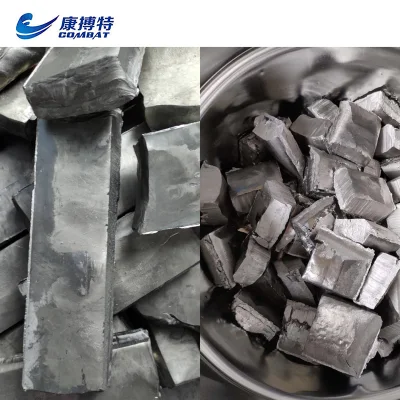

Tungsten Copper Alloy

Content: Material: WCu (W50 W55 W60 W65 W70Cu, W75Cu, W80Cu, W85Cu, W90Cu, etc)

W90-97NiFe(Magnetic) & W90-97NiCu(Nonmagnetic)Density:16.8-18.8g/cm3

Property of tungsten alloy

AMST 21014 class 190%WNiFe, 90%WNiCuDensity : 17.0Hardness: 32HRC maxElongation: 5-20%AMST 21014 class 292.5%WNiFe, 92.5%WNiCuDensity : 17.2Hardness: 33HRC maxElongation: 5-15%AMST 21014 class 395%WNiFe, W95NiCuDensity : 18.0Hardness: 34HRC maxElongation: 3-10%AMST 21014 class 497.5%WNiFe, W97.5NiCuDensity : 18.85Hardness: 35HRC maxElongation: 1-8%

Tungsten high heavy alloy

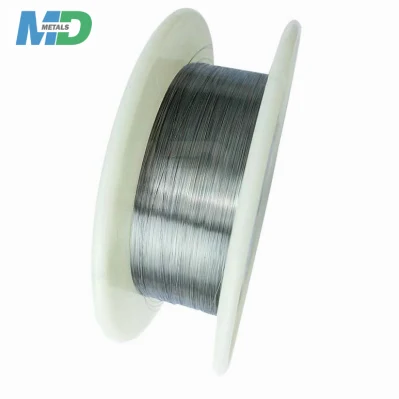

- Material: W90-97NiFe(Magnetic) & W90-97NiCu(Nonmagnetic) - Density:16.8-18.8g/cm3 - Rods Size:dia(1.5 -200) x Length<500mm Plate size: 0.1min Thickness*W*L

1. Tungsten copper alloy rod Specification:Material: W50-90Cu10-50Density: 11.85g/cm3-16.75g/cm3Product standard: GB8320-87WCu alloy foil size: Thickness(0.08-0.7mm)*Width<120mm*Length<300mmWCu alloy sheet size: diameter(3-100mm)*L<500mm

2. Pure tungsten/molybdenum rod surface finish:Black: surface is as swaged or as drawn, retaining a ciating of processing lubricants and oxides.Cleaned: Surface is chemically cleaned to removed all lubricants and oxides.Ground: Surface is centerless to ground to remove all coating and to achieve precise diameter control.3. Pure tungsten rod dimension:

| TungstenContent | Type | Diameter(mm) | Dia.Tolerance(mm) | Length(mm) | L tolerance(mm) |

| 99.95% | Sintering rod | 40-100 | ±3 | 500max | ±5 |

| 99.95% | Froged rod | 20-80 | ±2 | 800max | ±5 |

| 99.95% | Ground rod | 2-60 | ±0.1 | 600max | ±1 |

4. Chemical composition

| Content of Tungsten | Content of all other elements | Content of each element |

| ≥99.95% | ≤0.05% | ≤0.01% |

5. Application & Features

Used as electrodes in the field of rare earth metal industry; For producing electric light source parts and electric vacuum components; Used in electric boosting glass kiln electrode; Suitable for producing ion implantation parts; For producing heating elements and refractory parts in high teperature furnaces; Very good interlaminar strength at strong thermal and mechanical loadings6. More information about us:We promise you -- The advantage of us:

1) products quality, with many years of producing experience

2) low price in the market, and factory direct sales.

3) the whole production line from powder to finished products, top and steady quality assured 4) good packing for safe exprot delivery, and fast manufacturing time

5) fast delivery and best after-sale service.

Send to us