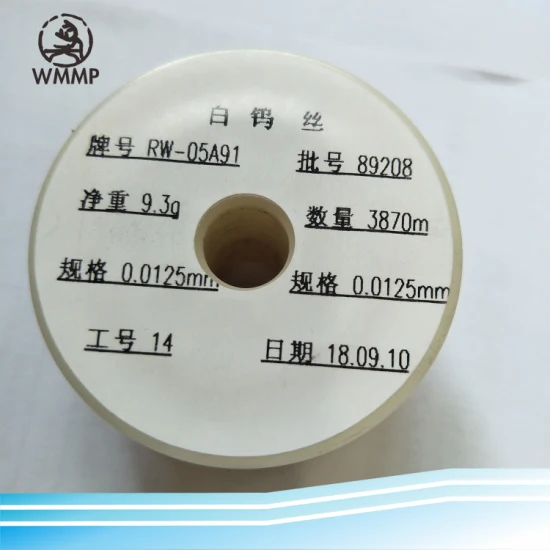

Dia0.18mm EDM Molybdenum Wire, Black Tungsten Wire Molybdenum Wire for EDM Machine

Pure 99.95% black molybdenum EDM wire dia0.18mm each roll 2km for CNC cutting machinemolybdenum wire Purity: Mo≥99.95%De

Basic Info

| Model NO. | Mo1 |

| Application | Aviation, Electronics, Industrial, Medical, Chemical, EDM Cutting |

| Standard | GB, ASTM |

| Purity | >99.95% |

| Alloy | Non-alloy |

| Type | Molybdenum Wire |

| Powder | Not Powder |

| Transport Package | Standard Exported Plywood Case/Wooden Packing |

| Specification | Dia0.04-3.2mm |

| Trademark | WMMP |

| Origin | China |

| HS Code | 8102960000 |

| Production Capacity | 15tons/Month |

Product Description

Pure 99.95% black molybdenum EDM wire dia0.18mm each roll 2km for CNC cutting machinemolybdenum wirePurity: Mo≥99.95%Density: >10.2g/cm3Size: dia0.08-3.0mmStandard: GB/T 4182 or ASTMSurface: Molybdenum wire is regular black covered with graphite.After graphite removed,it is metallic luster.Pure molybdenum wire chemical component

| Content of molybdenum | Content of all other elements | Content of each element |

| ≥99.95% | ≤0.05% | ≤0.01% |

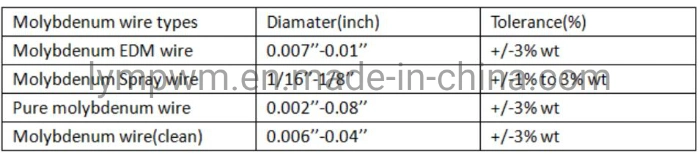

Our molybdenum wire type:

Diameter (μm) | Weight (mg/200mm) | Weight (mg/200mg) Tolerance (%) | Diameter Tolerance (%) | ||

| Grade 1 | Grade 2 | Grade 1 | Grade 2 | ||

| 20≤d<30 | 0.65~1.47 | ±2.5 | ±3 | ||

| 30≤d<40 | >1.47~2.61 | ±2.0 | ±3 | ||

| 40≤d<100 | >2.61~16.33 | ±1.5 | ±3 | ||

| 100≤d<400 | >16.33~256.2 | ±1.5 | ±4 | ||

| 400≤d<600 | ±1.5 | ±2.5 | |||

| 600≤d<3200 | ±1.0 | ±2.0 | |||

Very good interlaminar strength at strong thermal and mechanical loadings

Application of Molybdenum wire

1) Molybdenum wire is widely for wire cutting machine.

2) Molybdenum wire is used in lighting (such as used as mandrel, support wire, lead-in wire, etc.),

3) For producing heating components, heating material in furnace, wire-cutting, spraying wire, glass to metal seals, printer pins, coil-mandrels, hooks for ordinary lights, grids for electronic tubes and heaters for hi-temperature furnaces; also hi-temperature structural for halogen lamps, heaters for hi-temperature furnace, rotation axis for X-ray and other fields and so on.

4) Used for spraying wear and tear parts of automobile and other machine to enhance heir wearability.

Our Mo wire packing&delivery:

1)paper wrapped the sheets, then plastic paper protected from moisture2)Foam board around the the inner wooden case3)Standard exported plywood case outside

DeliverySample Delivery: 7-10 days is ok

Big order quantity: Usually we can supply within 20 days

Shipment Methods:

By express(EMS,TNT,DHL,UPS,FedEx)

By Sea or Air transportation

By landBy YWWEN special line or other special line

We also can deliver as the customers' need,send the material to the port.We also supply high temperature molybdenum wire(TZM wire)

| Term | High Temperature TZM Molybdenum Wires |

| Material | Molybdenum |

| Shape | Wire |

| Color | Metallic |

| Diameter | 0.08mm-0.3mm |

| Length | 2000m-2400m |

| Grade | TZM |

| Diameter(mm) | Diameter telorance, % | Weight ( 200mm ), mg | Length min, m |

| 0.015−0.03 | / | 0.360−1.440 | 1500m -2000m |

| 0.03−0.1 | 1.440−16.00 | ||

| 0.1−0.2 | ±0.5−±1.5 | 16.00−256 | |

| 0.2−0.4 | |||

| 0.4−0.7 | ±1.5−±2.5 | / | |

| 0.7−1.8 | ±1.0−±2.0 |

The advantage of us:

1) We already have more than 11 years tungsten&molybdenum material producing and exporting experience

2) Competitive price in the market,factory direct sales.

3) the whole production line from powder to finished products, top and steady quality assured

4) fast delivery and best after-sale service

5) Every month we export more W&Mo material to European,America,New Zealand,Korea etc

Send to us